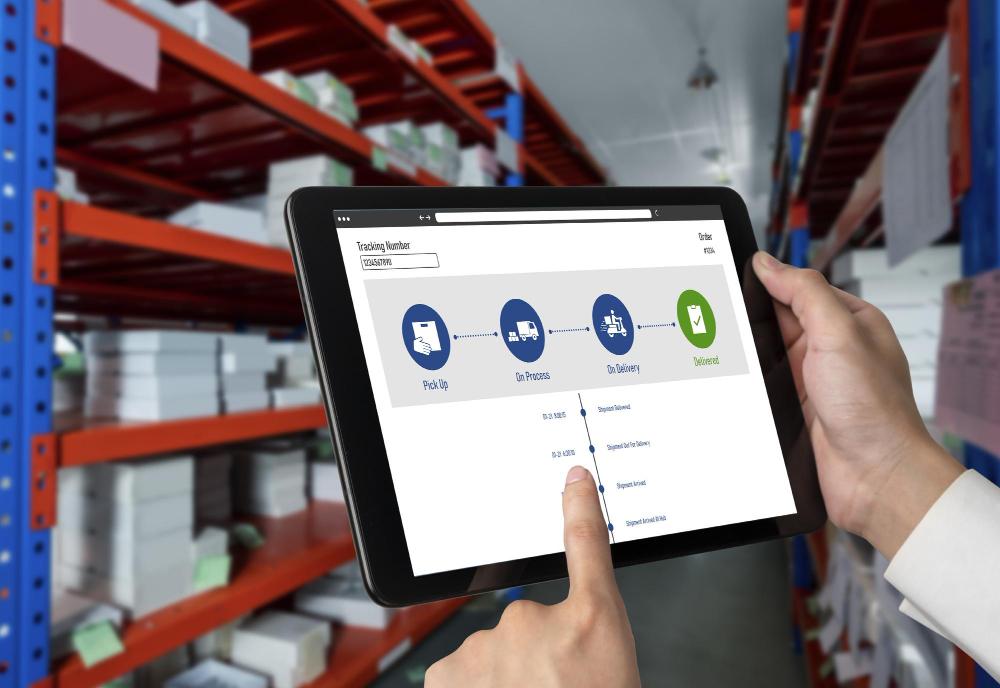

An automated supply chain is a system where technology manages and monitors the flow of goods and materials. This can include sensors and RFID tags to track inventory levels to automated machines that handle picking, packing and shipping orders.

Technology plays a significant role in automating the supply chain, and various benefits can be accomplished. For example, automated systems can help enhance accuracy and productivity while minimising costs. In addition, automated supply chains can help to improve communication and collaboration between different parts of the supply chain. Also, an automated supply chain module of ERP software can help you get enhanced productivity.

Benefits of Automated ERP Software Supply Chain

There are many benefits that manufacturers can reap by implementing automated supply chains. If you’re involved in supply chain management, it is essential to have an efficient and effective system.

There are many benefits to using an automated supply chain ERP system:

1. Increased accuracy and visibility – When you have a central system that feeds all your data, it’s much easier to track and manage. This can lead to increased accuracy and visibility of your supply chain, which is essential for making sure that everything runs smoothly.

2. Improved efficiency – An automated system can help to streamline your processes and make them more efficient. It can free up required time and resources that can be better spent elsewhere.

3. Cost savings – Automating your supply chain can help reduce costs in terms of time and money. By having an advanced system in place that is efficient and effective, you can avoid wasted resources and save money in the long run.

4. Better customer service – When your supply chain is running smoothly, it can lead to improved customer service. This is because your customers will receive their orders on time and as expected.

5. Increased competitiveness – A well-run supply chain can give you a competitive edge over your rivals. This is because you’ll respond efficiently to market changes and ensure that your customers are always getting what they need.

If you wish to improve your supply chain management, then an automated ERP system is definitely worth considering. There are many benefits that such a system can bring, and it can really help to take your business to the next level.

Types of Automated Supply Chain in ERP Software

There are many different types of automated supply chain systems, each with its own advantages and disadvantages. Here are the most common types:

1. Conveyor Systems

Conveyor systems are the most common type of automated supply chain system. They are used in different industries, from manufacturing to logistics. Conveyor systems are very efficient at moving large quantities of goods quickly and smoothly. However, they can be expensive to install and maintain, and they are only sometimes the best solution for small or delicate items.

2. Robotics

Robotics is another common type of automated supply chain system. Robotics can be used for a variety of tasks, from sorting and packing orders to loading and unloading trucks. Robotic systems are usually very efficient and can often work faster than human workers. However, they can be expensive to purchase and maintain and typically require a lot of space.

3. Warehouse Management Systems

Warehouse management systems are automated systems that track inventory and manage warehouse operations. These systems can be beneficial in reducing the amount of time and labour needed to manage a warehouse. However, they can be expensive to implement and maintain and may not be the best solution for smaller warehouses.

4. Transportation Management Systems

Transportation management systems are automated systems that are used to plan and execute transportation operations. These systems can be beneficial in reducing the cost and time of transportation operations. However, they can be expensive to implement and maintain, and there may be better solutions for smaller companies or companies with complex transportation needs.

What are the characteristics of an automated ERP supply chain?

An automated ERP supply chain is one that can operate without any help from the outside. This means it can procure and manage its resources and produce and distribute its products. Several characteristics are common to all supply chains. These include self-reliance, self-organisation, and self-regulation.

An automated ERP supply chain typically includes the following characteristics:

1. Data Collection: Data is collected electronically from various sources within the supply chain, including suppliers, manufacturers, distributors, and customers. This data is then fed into the ERP system for analysis and decision-making.

2. Visibility and Transparency: All supply chain members have visibility into the data, leading to improved decision-making and coordination.

3. Efficiency and Accuracy: Automated ERP systems help to reduce errors and improve accuracy throughout the supply chain.

4. Costs: Automated ERP systems can help to reduce costs by streamlining processes and increasing efficiency.

5. Customer Satisfaction: Automated ERP systems can help to improve customer service by providing accurate information and reducing lead times.

How can you implement an automated supply chain module of ERP software?

There are some factors to consider when implementing an automated supply chain. One way is to have a completely automated system where all the communication and transactions are done through computer systems. This can be expensive and difficult to set up, but it can be very efficient. Alternatively, you can have a system where a certain amount of manual intervention is required, but most of the work is done automatically. This can be more affordable and easier to set up, but it may be less efficient. Whichever method you choose, it is essential to ensure that the systems are integrated and working well together.

The characteristics of an automated supply chain make it an ideal choice for businesses looking for a more efficient and agile operation. By eliminating the need to consult with other members of the chain, each member can operate more automated, leading to faster decision-making and a more streamlined operation.

The Challenges of Automated ERP Supply Chain

There are many challenges associated with automated ERP system supply chain management processes. The first one is data interoperability. In order for automation to be successful, different software applications and systems must be able to share data seamlessly. This can often be difficult, as other software applications may use different formats for storing and exchanging data.

One of the main challenges is also fetching real-time data. In order for automated supply chain processes to be effective, managers must have access to accurate and up-to-date information. This can be a challenge, as many supply chain management processes span multiple geographical locations and involve a large number of stakeholders.

Another challenge associated with automating supply chain management processes is the need for sophisticated algorithms. Many supply chain management processes are highly complex and require intricate algorithms in order to be optimised. These algorithms are necessary for automated supply chain processes to function effectively.

Automation has the potential to revolutionise supply chains, making them more efficient, responsive, and resilient. With new technology, challenges must be considered prior it can reach its full potential.

The most significant challenge is the deficiency of standardisation. Various automation technologies are available, each with its strengths and weaknesses. Companies need help to choose the right technology for their needs and find suppliers to provide it.

What are the future trends for the automated ERP supply chain?

The future of automated supply chains is bright, with many companies investing in the technology. Some of the future trends for independent ERP supply chains include:

1. Increased robotics and artificial intelligence (AI) use in warehouses and distribution centres.

2. More widespread use of drones for delivery and inventory management.

3. Growth of the “Internet of Things” (IoT) and using sensors and intelligent devices

to optimise supply chain operations.

4. Enhanced use of blockchain technology to secure and track shipments.

5. Development of self-driving vehicles for the transport of goods.

These trends point to a future where automated supply chains are more efficient and effective, resulting in lower costs and faster delivery times.

With the benefits that automated ERP supply chains offer, it is clear that they are the future of supply chains. Since new technologies continue to develop, we can expect even more impressive advances in ERP supply chain modules, making them more efficient and reliable than ever.

Undoubtedly, the automated supply chain acts as a catalyst for the industry, offering significant profit margins and accomplishing cost controls. As the world is becoming increasingly reliant on technology, the future of the supply chain is looking more and more automated. This means that businesses will need to invest in automation to stay ahead of the competition.

Down the Line

The benefits of ERP software supply chain management for manufacturers are many and varied. The most significant advantages are reduced costs and improved efficiency. By automating the supply chain management process, manufacturers can streamline their operations and avoid the waste and inefficiency that often plague manual processes.

In summary, automated ERP systems can provide real-time data and visibility into the supply chain, which can help manufacturers make more informed decisions about production and inventory levels. Ultimately, the goal of automatic supply chain management is to help manufacturers become more agile and responsive to the ever-changing needs of their customers.

Author’s Bio:

Deepali Daiya is a communication expert who excels in understanding customer needs. She writes powerful sales scripts and articles with very high conversion rates. Currently, she is associated with Sage Software Solutions, a leading distributor of high-quality ERP and CRM systems to small and mid-sized businesses in India.